Adhesive tape is a product that is made of cloth, paper, film, etc. as the base material, and is processed into a tape by evenly coating the adhesive on various base materials and then made into a reel for supply. According to the base material, it can be divided into BOPP tape, cloth-based tape, kraft paper tape, masking tape, fiber tape, PVC tape, PE foam tape, etc. According to the effect, it can be divided into high-temperature tape, double-sided tape, insulation tape, special tape, etc., and different effects are suitable for different use needs. According to the type of adhesive, it can be specifically divided into water-based tape, oil-based tape, solvent-based tape, hot-melt tape, natural rubber tape, etc. With the development of the economy and the advancement of science and technology, China has become a major processing and production plant and consumer in the world's adhesive industry. After so many years of continuous development, the application fields of tape are increasing, covering electronics, communications, packaging, construction, papermaking, woodworking, aerospace, automobiles, textiles, metallurgy, machinery manufacturing, medical industries, etc. There is no doubt that the adhesive industry has become an important and dynamic industry in my country's chemical industry.

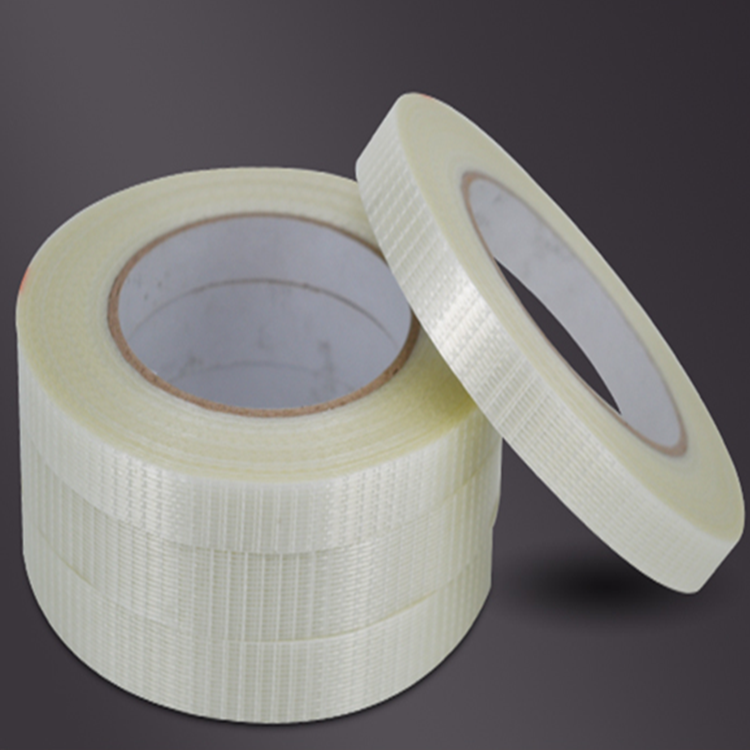

From the demand point of view, there are many categories of adhesive tapes, and the downstream can be used in civil markets such as building decoration, household daily necessities, and packaging. At the same time, adhesive tapes can also be used in industrial fields such as automobiles, electronic components, shipbuilding, and aerospace. Taking the automotive industry as an example, in recent years, the automotive market has increasingly demanded high-performance and environmentally friendly tapes such as water-based PVC automotive wiring harness tape and water-based masking paper. Obviously, the traditional adhesive material manufacturing industry has gradually evolved into an emerging material industry with high technological content, wide application fields, and many downstream industry segments. Taking fiber tape as an example, it uses high-strength glass fiber yarn or cloth as a reinforcing material, PET film as a backing material, and pressure-sensitive adhesive as a binder, and is coated according to process treatment. The product has the characteristics of clean and tidy appearance, strong adhesion, no residual glue, high strength, and not easy to cause deformation when shearing. At this stage, it has been widely used in heavy packaging and component fixing or bundling in furniture, wood, steel, ships, machinery, electrical appliances and other industries. While tapes are deeply integrated into people's daily lives, they play an increasingly important role in modern industrial production, and their technical content is constantly improving.

Overall, the downstream industry is growing steadily, bringing considerable market capacity for the development of the adhesive tape industry.

Of course, we also need to clearly realize that although the current market demand for my country's adhesive materials industry is strong and the industry is growing rapidly, most of China's adhesive tape products are low-end products with low technical content, and there is a big gap with foreign advanced companies. The supply of high-end products in the industry is still monopolized by international giants such as 3M, Henkel, Tesa, and Nitto. Internationally renowned adhesive tape manufacturers (such as 3M and Tesa) have almost monopolized the high-end market in the fields of electronics and automobiles with their rich industry experience, leading technical strength, strong product quality stability, and high brand awareness. Domestic manufacturers have rapidly developed and grown with their cost advantages and occupied most of the low-end and mid-end markets.

Against the backdrop of my country's industrial structure adjustment and upgrading, the industry integration and upgrading of the adhesive materials industry will also accelerate. Enterprises with standardized operation, adequate environmental protection investment, continuous research and development of new technologies and new products, advanced technology and strong production cost control capabilities will be the industry leaders, and small and medium-sized manufacturers with weak technical strength will be eliminated by the market.

Faced with the serious homogeneity of adhesive tape products and the large gap between product technology and that of foreign advanced enterprises, domestic adhesive tape manufacturers have actively increased their efforts in the research and development and promotion of new products, continuously adjusted product structure, and improved production processes. Their competitiveness in the mid-to-high-end market has been significantly enhanced. The adjustment and upgrading of industrial structure are accelerating. Enterprises with stable product quality, comprehensive supply capabilities, and the ability to provide customized solutions in a timely manner according to changes in market and customer needs are expected to achieve industry leadership. In addition, with the trend of increasingly tightening environmental protection policies, special, environmentally friendly and high-tech products will have greater room for development.